News & Press

-

- News

- Jul 5, 2023

HKC – positive news or business as usual?

Last week’s news that the Hongkong Convention on the Safe and Environmentally sound Recycling of S…

-

- News, Projects

- Mar 14, 2022

Dismantling of the MS Fugro Adventurer

Sea2Cradle is pleased to announce that Fugro has trusted us in facilitating the safe and sustainable…

![Fugro Adventurer]()

-

- News

- Nov 17, 2021

IHM Advances the cause for responsible ship recycling

In November 2021, Sea2Cradle’s Commercial Director, Bert van Grieken, was interviewed in the magaz…

![IHM Advances the cause for responsible SRR]()

-

- News

- Aug 15, 2021

“The ship recycled … ” – Sea2Cradle featured in SWZ Maritime

Sea2Cradle was invited as ‘recycling expert’ for an interview in the Special edition on Responsi…

![101 P1030220]()

-

- News

- Aug 1, 2021

“Onwaardig einde ….” – Sea2Cradle featured in Europoort Kringen

Sea2Cradle was interviewed for the magazine of Europoort Kringen regarding the controversial beachin…

![101 P1030193]()

-

- News

- Mar 16, 2021

Sea2Cradle panellist at the Standard Club Webinar on Ship Recycling

On 17 March 2021 Sea2Cradle took part in a Webinar organized by the Standard Club. The applicable re…

-

- News

- Mar 3, 2021

Sea2Cradle has been interviewed by the BBC

CMV Photo of the cruise vessel Marco Polo Sea2Cradle was interviewed by the BBC on an article and…

![Marco-Polo-CMV-photo.efcc8c]()

-

- Press

- Aug 5, 2020

Tribute article in Tradewinds about the late Tom Peter Blankestijn

Sea2Cradle invites you to read below article published in Tradewinds about Sea2Cradle's former manag…

![TP tradewinds 2019 vierkant 2]()

-

- Press, Projects

- Aug 3, 2020

New collaboration between Carnival Corporation and Sea2cradle on responsible recycling of cruise vessels

Sea2Cradle is pleased to announce a collaboration with Carnival Corporation for the safe and environ…

![DSCN8700 (2)]()

-

- Press

- Jul 10, 2020

“Opgeruimd staat netjes” – Sea2Cradle in TU Magazine “Boegbeeld”

Voor "Boegbeeld", het verenigingsblad van de studievereniging van maritieme techniek van de Technisc…

![OLYMPUS DIGITAL CAMERA]()

-

- Press

- Jun 22, 2020

How it is done

Sea2Cradle was featured in the Dutch television programme of RTL “How it is done” on 20 June 202…

![how its done]()

-

- News, Projects

- Jan 21, 2020

Decommissioning of the “Samskip Frost”

Sea2Cradle is pleased to announce that Samskip has trusted us to facilitate the green recycling of t…

![samskip-frost-2-600x419]()

-

- News

- Dec 4, 2019

Sea2Cradle participated at Salvage & Wreck Conference on Waste Management

On the 4th of December 2019, Sea2Cradle's Director, Wouter Rozenveld, participated in a discussion p…

![20191204_150701-Wouter-SW-Panel-600x407]()

-

- News

- Aug 12, 2019

In Memoriam – Tom Peter Blankestijn

On 12th of August 2019 our Managing Director, friend and colleague, Tom Peter Blankestijn, suddenly …

-

- News, Press

- Jul 19, 2019

Mega Box Ship Bulletin – Transboundary Movement of Waste

In recent years, Sea2Cradle has also provided consultancy and recycling-supervision services in a nu…

![20181121_080912]()

-

- News

- Jun 19, 2019

Sea2Cradle renewed certification as Approved Service Supplier (IHMs) for Lloyd’s Register

As per 19 June 2019, Sea2Cradle was again approved by Lloyd’s Register as Service Supplier for Inv…

-

- Press

- Apr 1, 2019

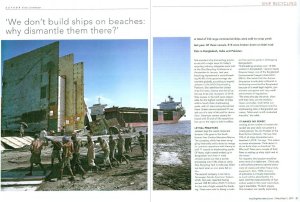

Sea2Cradle featured in Recycling International

In March/April 2019 Sea2Cradle was featured in the magazine of Recycling International. The article …

![why dismantle on the beaches]()

-

- Press

- Mar 20, 2019

Interview “Maritime Holland” – Responsible Ship Recycling

Maritime Holland has published an article on "The business of responsible ship breaking" in which Se…

![070 DSCN3051 (i) cutter with correct PPE at secondary cutting site]()

-

- News

- Aug 23, 2018

Sea2Cradle is now ISO 9001:2015 certified

Sea2Cradle is pleased to announce that we were approved for ISO 9001:2015 by Lloyd's Register and as…

-

- News

- Apr 21, 2018

Social gathering at Frank Fox’s retirement dinner

On Saturday 21st April 2018 Frank Fox celebrated his official retirement by giving a dinner party in…

-

- Press

- Nov 2, 2017

Clearing the beaches

Sea2Cradle was featured in the Magazine 'Inside Marine' with a profile of the company. To read more …

![103-DSCN5297 (2) oil boom in place]()

-

- Press, Projects

- Aug 16, 2017

A Clean Record

Sea2Cradle featured in the LandSeaAir Magazine (formerly Shipping & Marine) of August 2017. Amon…

![01 scraping away dirt until bare steel before cutting can be done]()

-

- Projects

- Jun 3, 2017

Project 117. The Sanitation and supervision of the M.v. Los Llanitos

In October 2015 the Bulk carrier “Los Llanitos” was grounded near Barra de Navidad, Mexico, duri…

![117 Los Llanitos DSC_0376-1 (ivw2ct) 2]()

-

- Press

- Aug 10, 2016

Interview Havenkrant Rotterdam “Schone Sloper”

Tom Peter Blankestijn was interviewed in the Havenkrant of the Port of Rotterdam on Sea2Cradle’s c…

![Schone Sloper 2016]()

-

- News

- Jul 19, 2016

Sea2Cradle was approved by Lloyd’s Register (LR) as Service Supplier for Inventory of Hazardous Materials

The Inventory of Hazardous Materials (IHM) is one of the main requirements of both the Hong Kong Con…

-

- News

- Jun 21, 2016

Leyal becomes IMO HKC certified

On 20 June 2016 Leyal issued a press release announcing their IMO Hong Kong Convention compliance ce…

-

- Press, Projects

- Dec 15, 2015

Putting the Maersk Endurer to rest

In December 2015 Maersk Drilling interviewed Tom Peter Blankestijn on 'putting the Maersk Endurer to…

![104 DSCN0574 (ivw2ct2) WM]()

-

- Press, Projects

- Nov 2, 2015

Platform for growth

Sea2Cradle featured in the Shipping & Marine Magazine “Focused on the Future”. You can read …

![IMG_0170 (ivw2ct)]()

-

- News, Projects

- Oct 1, 2015

Project 103. Recycling of m.v. “Tristan”

In the summer of 2015, Sea2Cradle was granted another recycling project by Wallenius Shipping for th…

![103 Tristan 4016-Tristan ivw2ct final]()

-

- Projects

- Sep 23, 2015

Maersk Endurer arrived in Zhoushan

As announced in August, when Maersk Drilling granted Sea2Cradle the decommissioning of their Jack-up…

![104 Maersk Endurer site wm-]()

-

- News

- Sep 9, 2015

Marine Technology students visit Zhoushan Changhong Int. Shipyard

In view of Sea2Cradle’s partnership with the Delft University of Technology, we are pleased to inf…

![DSC_0505 (3)]()

-

- News, Projects

- Aug 3, 2015

Decommissioning of the rig “Maersk Endurer”

Sea2Cradle has been awarded another prestigious project. Maersk Drilling has granted us the demoliti…

![Maersk Endurer 4]()

-

- Press, Projects

- Jun 30, 2015

“Getting better at marine recycling”

Sea2Cradle’s company profile was featured in the magazine of GreenPort on 30 June 2015 in relation…

![SF Drydock 01 DSCN6624 )2)]()

-

- News

- May 26, 2015

President Xi Jinping visits Zhoushan Changhong International Shipyard

On 26 May 2015 President Xi made a visit to the Zhoushan Province in order to investigate the curren…

![President Xi Jinping at Changhong 2]()

-

- Press

- Apr 10, 2015

Interview in MVO Nederland ‘Grensverleggers’ – Schepen slopen hoeft geen smerige business te zijn

As keen participant in ‘Grensverleggers’ (Groundbreakers) Tom Peter Blankestijn was interviewed …

-

- Projects

- Feb 4, 2015

Project 99. Recycling of the “San Francisco Dry Dock #1”

A prestigious project at the Port of San Francisco (USA). In collaboration with Dockwise, Sea2Cradle…

![99. SF Drydock (IMG_9824 (Argonautics Marine Engineering Inc.) 2]()

-

- Projects

- Jan 30, 2015

Project 100. Recycling of the “Sirius Voyager”

Sea2Cradle has reached its 100th project! This milestone concerns a crude oil tanker, which arrived …

![100. Sirius Voyager (DSCN6436)]()

-

- Press

- Jan 13, 2015

Circle of Life

Sea2Cradle's company profile was featured in the magazine of Shipping & Marine in their 117th ed…

![steel cutting on site (300 dpi)]()

-

- News

- Dec 16, 2014

Sea2Cradle assists two Chinese recycling yards in bid for EU approval as green facilities

Sea2Cradle is proud to have been involved in the application of two Chinese recycling yards to the E…

-

- Projects

- Jul 14, 2014

Project 84. Recycling of the “Kulluk” oil rig

Sea2Cradle has successfully completed the recycling of its first oil rig: “Kulluk”. As in all ou…

![OLYMPUS DIGITAL CAMERA]()